Features of compact induction melting furnace

Features of compact induction melting furnace (for melting up to 5 kg of metal)

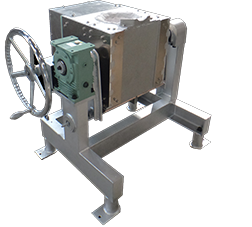

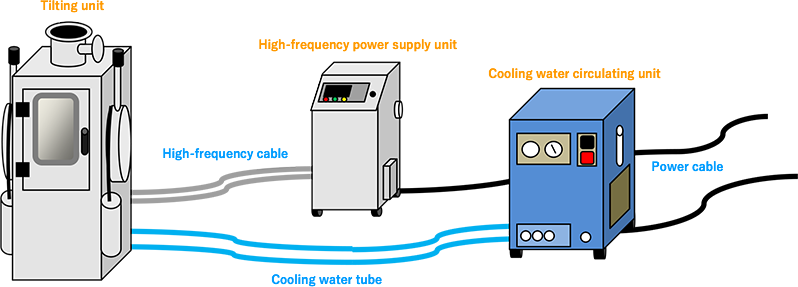

- Designed for safety. The melting furnace, tilting device, and casting mold are all contained inside the unit’s box, eliminating the risk of molten metal splattering outside.

- The combination of induction heating and graphite crucible enables rapid melting operation.

- Our double-crucible system is designed to contain all molten metal even if one crucible is damaged and leaks. The graphite crucible can be easily replaced.

- DHF high-frequency power supply unit is built with an overheating prevention timer, eliminating the risk of human error.

- By using readily available standard-type graphite crucibles (commercial products), the cost of replacing crucibles is reduced.

- Meltable materials

- Copper, zinc, gold, silver, iron, etc.

- Sample melting times

- ・0.5 kg brass: about 9 mins

- ・3 kg copper: about 16 mins

- *The times above apply to continuous melting operation.

Features of compact induction melting furnace (for melting 10 to 30 kg of metal)

- Designed for safety. The coil protection sensor is contained, ensuring safety even if molten metal leaks.

- The high-frequency power supply unit is simple to operate and requires no specialized skills.

- By using readily available standard-type graphite crucibles (commercial products), the cost of replacing crucibles is reduced.

- Meltable materials

- Copper, zinc, gold, silver, iron, etc.

- Sample melting times

- ・30 kg cast iron: about 40 mins

- *The time above applies to continuous melting operation.

Configuration of compact induction melting furnace (for melting up to 5 kg of metal)

Specifications of compact induction melting furnace using Alumina-type crucible

- *1: Please contact us if the required melting temperature is more than 1600 ℃.

- *2: Please contact us if the required frequency is more than 10kHz.

Specifications of induction melting furnace using Graphite-type crucible

- *1: Please contact us if the required melting temperature is more than 1500 ℃.

- *2: Please contact us if the required frequency is more than 40kHz.

- *Cooling water circulating unit and dust collecting unit are optional.

- *The melting amount varies depending on the shape of melting materials.

Sample heating test

We conduct sample heating tests upon request at our testing facility.